Although machines like CNC waterjet cutters work directly on meals items for cutting, Other individuals are used for packing or generating cooking equipment. Some typical applications are:

The precise machine can get rid of the aspect after it's been produced. Depending upon the requirements, the aspect might be despatched for secondary strategies which include grinding or sprucing. Even so, a precision CNC-machined done products demands no added processing in many situations.

CNC Precision machining is getting level of popularity within the manufacturing industry thanks to its a lot of applications, inexpensive, and rapid turnaround times. The method is usually utilized in many different industries, like:

The applications of CNC systems in these sectors are large, from intricate customized designs for weapon bodies into a missile’s interior parts. Here are a few from the parts that are created employing a CNC manufacturing system:

When investigating the background in the NC machine, Jone T. Parsons produced a method to manage the machine tool using punch cards in 1940. Soon after the primary demonstration, a industrial NC machine was launched in 1952.

Laptop-aided design and style generates a computerized graphical representation of your portion. This illustration is straightforward to be aware of for designers, operators, and producers. Even so, the CNC machines which make the element do indirectly grasp this electronic structure.

A corporation that designs custom parts for that automotive industry may use a hybrid manufacturing process to make complex geometries and intricate parts. The method commences with 3D printing, wherever a polymer materials is used being a foundation layer. Then, CNC machining refines and designs the ultimate part. This mix of processes allows for higher design overall flexibility than either procedure could realize on its own.

Pc Aided Manufacturing (CAM) computer software employs two forms of codes: G and M codes. The G code regulates the cutting tool’s coordinates. The M code manages the machine’s auxiliary capabilities, which include turning on or off the coolant movement.

Extraordinary rigidity is essential for micro-Swiss turning. Though enabling us to attain high-quality finishes and increase tool daily life, Swiss turning also permits bigger speeds and shorter cycle occasions due to the fact vibrations are absorbed into machine mass. Extraordinary rigidity enables Swiss turning of a wide variety of materials, together with titanium, stainless steel, valuable metals, MP35N, PEEK, Ultem, and so forth. It can be notice to element that makes Nanotech Precision, LLC the Swiss turning firm of option for professional medical Swiss machining and Swiss turning.

CNC machines have already been integral to mass production since the seventies, enabling companies to achieve the consistency and performance needed for giant-scale production. The automation of CNC processes has even further Increased productivity, lessening the need for guide labor.

But what is CNC Machining, How can it differ from standard Machining, and why are precision CNC machines pivotal for producing best-high quality CNC parts? On this in depth tutorial, we’ll go over these issues in detail.

This informative article explores how diverse industries use CNC machines, the historical involvement and evolution of CNC technology, and what the future holds as we move in the 2030s.

The massive-scale manufacturing method for boats and various drinking water transportation calls for automation to fulfill the manufacturing deadlines and high-quality Regulate. This is only attainable with CNC machining.

The team — led by previous U.N. weapons inspector David Albright and researchers Sarah Burkhard and Spencer Faragasso — discovered that numerous on the products of CNC tools explained within the data were in more info all probability topic to export controls, but claimed a definitive assessment would call for input with the Taiwanese government.

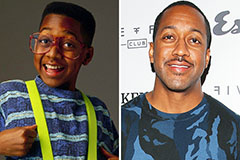

Jaleel White Then & Now!

Jaleel White Then & Now! Tia Carrere Then & Now!

Tia Carrere Then & Now! Brian Bonsall Then & Now!

Brian Bonsall Then & Now! Michael Bower Then & Now!

Michael Bower Then & Now! Robin McGraw Then & Now!

Robin McGraw Then & Now!